Introduction:

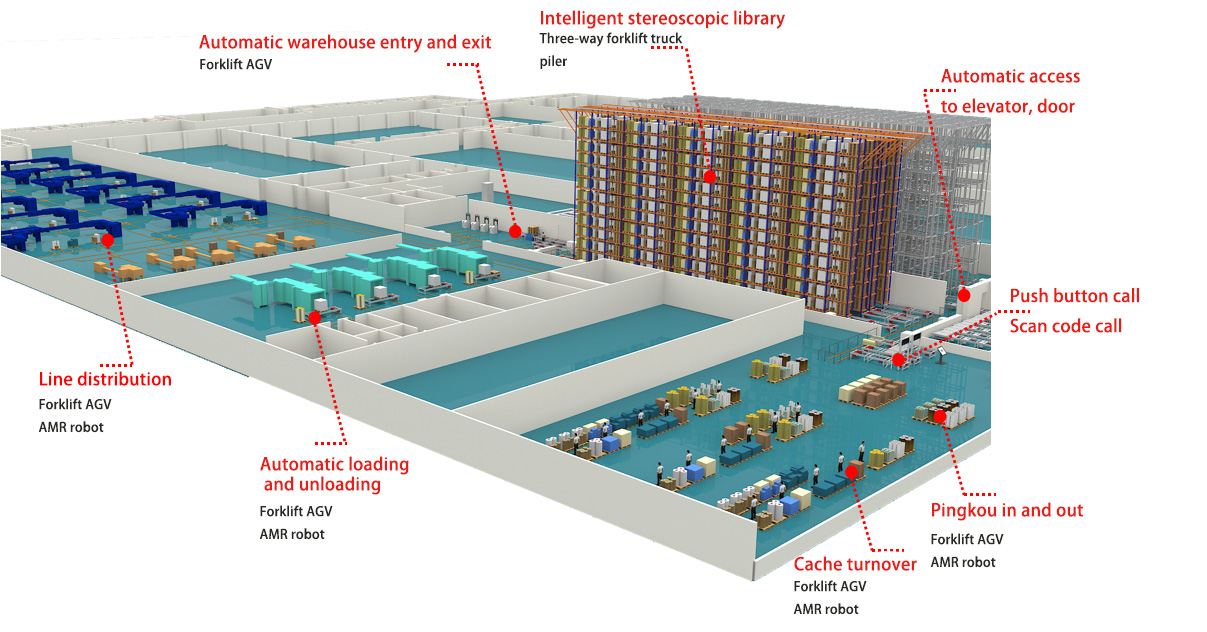

Adopt EGO's Forklift AGV, AMR robot, dispatching system, warehouse management system and supporting software and hardware products to realize the management and transportation of intelligent logistics in the whole plant, including intelligent three-dimensional warehouse, automatic warehouse in and out, horizontal warehouse management and automatic warehouse in and out, line distribution, automatic loading and unloading and material turnover, so as to reduce the participation of material distribution personnel in the production process, Improve production efficiency and production management level.

Advantages:

1. Laser navigation without changing the environment

Compatible with slam environment navigation and reflector navigation, flexible combination, suitable for various production environments

2. Multi machine cooperative operation, high efficiency

Dispatch multiple robots to work together for 24 hours, automatically allocate tasks according to production requirements, and dispatch robots to execute the optimal path

3. Unmanned distribution, safe and stable

Improve the production process, realize unmanned operation, avoid mistakes due to fatigue, safe and stable

4. Production digitization, visual management

The whole process data management of goods information and transportation information can be followed by production

5. Simple operation and low cost

The project has the advantages of simple deployment, short cycle, convenient maintenance and low cost. It can work across floors and regions, greatly reducing the labor cost

6. Fully independent research and development, customizable

The whole set of software and hardware system is completely independently developed, and the subsequent upgrading iteration is simple, which can be customized according to the functions required by customers.

Customer revenue:

1. Improve production efficiency

Automatically manage the warehouse, distribution of production raw materials, warehousing of finished products and turnover of buffer area, so as to realize the preparation and scheduling in advance and improve the overall production efficiency.

2. Reduce costs

Realize unmanned operation, reduce personnel participation and reduce labor cost.

3. High rate of return

Recoverable cost of the project in 1-2 years

4. Easy operation and maintenance

The implementation period of the project is 15-30 days, which is easy to operate and easy to maintain

| Model number | EAGV300 | |

| Basic parameter | Dimensions (L*W*H) (mm) | 954*594*268 |

| Weight (including battery) (kg) | 150 | |

| Load (kg) | 300 (customizable) | |

| Standard lifting height (mm) | 50/ No jacking | |

| property | Operating speed (adjustable in sections) (mm/s) | 0-1200 |

| Navigation mode | Laser navigation/QR code navigation | |

| Repeated positioning accuracy (mm) | ±10mm/±5mm | |

| Mode of movement | Forward and backward, turn left and right, rotate in place | |

| Power battery | Lithium battery type | Lithium iron phosphate |

| Battery capacity | 48V/25AH | |

| Rated operating time (h) | 6-8 | |

| Full charge time (h) | 2 | |

| Safety protection | Laser collision avoidance | Standard fitting |

| Mechanical collision avoidance | Standard fitting | |

| Emergency stop button, sound and light alarm | Standard fitting | |

| 3D visual recognition | Optional | |

| 3D visual collision avoidance | Optional | |

| other | Car display screen | — |

| Operation mode | Manual/automatic | |

| Charging mode | Manual/automatic | |

| Communication mode (roaming) | Wireless communication | |