AGV forklifts are autonomous guided vehicles that can autonomously navigate through programming or sensor technology without manual operation. They can both improve the efficiency of logistics and production lines, and reduce the risk of manual operation and human error.

Type design of AGV forklift

AGV forklifts include small forklifts, stacker forklifts, forward stacker forklifts, handling forklifts, balanced restacker forklifts and so on. AGV forklifts usually have a design similar to traditional forklifts, with forks and lifting mechanisms, they can insert forks under pallets or goods, and use the lifting mechanism to lift or lower the goods. It is mainly used for logistics turnover of moving and stacking goods in warehouses and production lines.

AGV forklift is an automatic unmanned forklift driven by battery. It is equipped with a control box and equipped with multiple safety anti-collision systems such as laser anti-collision, mechanical anti-collision and photoelectric anti-collision to realize automatic and safe driving of unmanned forklift. Independently developed navigation and positioning system, with AGV motion controller with independent property rights, to achieve positioning accuracy of ±10mm, compatible with SLAM environment navigation and reflective plate navigation two ways, with strong flexibility and intelligence, can run in complex path, multi-site reliable tracking, get away from the traditional operation of people and vehicles, automatic navigation driving, suitable for various production environments.

Working advantages of AGV forklift

Supporting AGV scheduling system and human-computer interaction software, all AGVs are managed through the deployed wireless network, AGV scheduling control and data monitoring are realized, and cargo information and transportation information are managed in the whole process of data, so that production can be tracked. The whole set of software and hardware system of easy robot is completely independent research and development, which can be customized according to customer needs. The subsequent upgrade iteration is simple. The system can also dock with MES/WMS production management system to create an intelligent production factory and realize the overall intelligent logistics management and transportation.

Efficiency of work

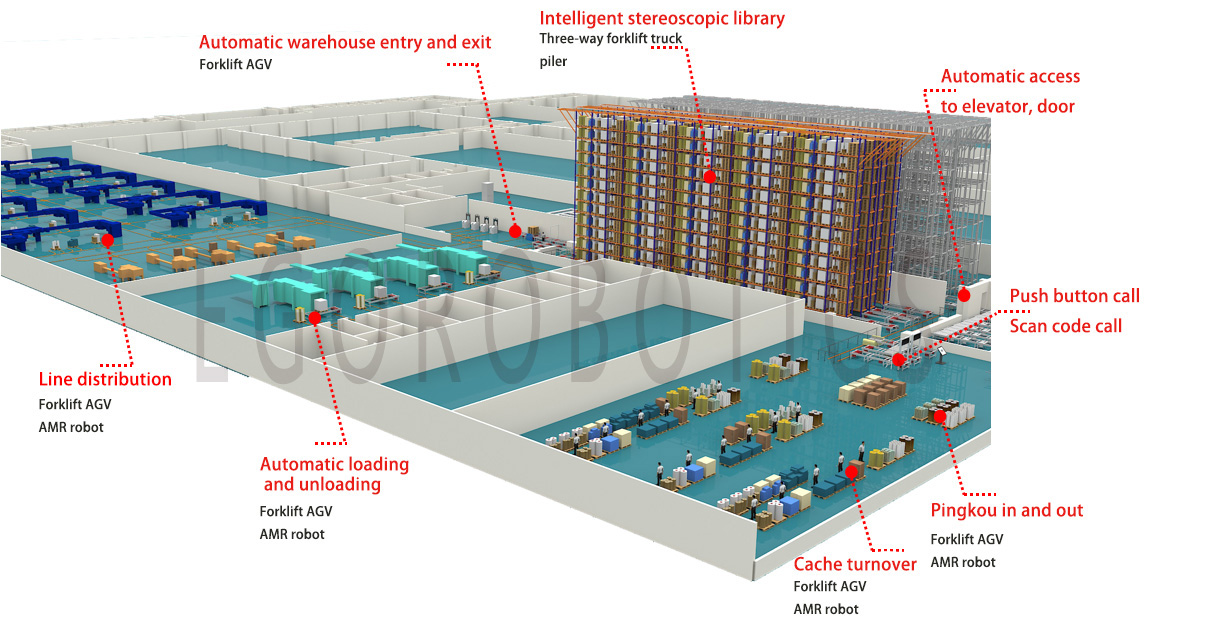

According to the changes of material positioning and production process in different factory workshops, the forklift AGV can be flexibly configured, which is more cost-effective than traditional conveyor belts and manual operations. Forklift AGV can also autonomously dock with other equipment in the production workshop and storage area, operate across floors and regions, greatly reduce labor costs, and realize full automation of production sequence and warehousing logistics.

The App market

In addition, the application of forklift AGV in the market is still expanding, not only for industry, agriculture, national defense, medical treatment, port, airport, medicine, chemistry, but also can be applied to warehouses, manufacturing, post office, library, tobacco, food and other industries. It can be seen that the future development and potential of forklift AGV is unlimited.

AGV forklifts, as an alternative to manual unmanned operations, can help enterprises reduce labor costs, improve work efficiency, and promote the intelligent transformation of enterprises through the process of human arrival to goods to people, so as to realize the new mode of intelligent storage production.

---- Responsible editor: Easy robot -- Editor: Xiao Yi

Copyright / (Easy robot intelligent logistics provider) Please indicate the source